| Sign In | Join Free | My hardware-wholesale.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My hardware-wholesale.com |

|

Brand Name : BOTO

Model Number : B-XD-120

Certification : MIL STD GB JIS JEDEC IEC ISO

Place of Origin : China

MOQ : 1PCS

Price : Discussible

Payment Terms : L/C, T/T, Western Union

Supply Ability : 1000PC/Month

Delivery Time : 15days

Packaging Details : wooden case

External Dim : 107x145x68

Model : B-XD-120

Internal : 40x35x35

HighTemp Rang : +80℃~200℃

Interior : SUS#304Stainless steel plate

Test Temp Rang : -40℃-150℃

Exterior : Coating or SUS#304Stainless steel plate

Low Temp Range : -10℃--60℃

name : Xenon Lamp Aging Chamber

brand : BOTO

Xenon Lamp Aging Chamber Lab Instrument Xenon Arc Test Chamber DIN50021 B-XD-120

Description:

A Xenon Lamp Aging Chamber is a device used to simulate the aging and degradation of materials exposed to sunlight or other forms of light. It is commonly used in industries such as automotive, aerospace, and textiles to test the durability and performance of materials under various environmental conditions.

The chamber consists of a xenon lamp that emits high-intensity light similar to sunlight. The lamp emits light in a spectrum that closely resembles natural sunlight, making it an ideal tool for simulating outdoor environmental conditions. The chamber also includes a system for controlling temperature and humidity to simulate different weather conditions.

Materials are placed inside the chamber and exposed to the light and environmental conditions for a specified period of time. The aging process is accelerated, allowing researchers to quickly evaluate the performance and durability of materials over an extended period of time. The results of these tests can be used to develop new materials or improve the performance of existing ones.

Usage:

As an AI language model, I do not have personal experiences or emotions, but I can provide you with information on how to use a Xenon Lamp Aging Chamber.

A Xenon Lamp Aging Chamber is used to simulate outdoor weathering conditions, such as sunlight and rain, in a controlled laboratory environment. The chamber is typically used to test the durability and resistance of materials, such as plastics, paints, and coatings, to weathering.

To use a Xenon Lamp Aging Chamber, follow these steps:

1. Prepare the sample material: Cut the material into the desired size and shape for testing.

2. Set the test parameters: Determine the exposure time, temperature, and humidity settings required for the test.

3. Place the sample material in the chamber: Securely place the material in the chamber, ensuring that it is not touching the lamp or any other components.

4. Turn on the chamber: Turn on the Xenon lamp and set the test parameters.

5. Monitor the test: Regularly monitor the sample material for any changes in color, texture, or other physical properties.

6. Evaluate the results: After the test is complete, evaluate the results to determine the material's durability and resistance to weathering.

It has the following performance characteristics:

1. Adopt full-spectrum xenon lamp luminescent tube;

2, a variety of filter system for choice;

3, rain spraying function;

4. Relative humidity control.

5, test chamber air temperature control system;

6. Sample fixer with irregular shape;

7. Cheap and fine xenon arc lamp tube.

8, xenon lamp aging test chamber has the characteristics of easy installation, convenient use and simple daily maintenance.

Model | B-XD-120 | B-XD-225 | B-XD-408 | B-XD-800 | |

Internal Dim(W*H*D) | 45x60x45 | 50x75x60 | 60x85x80 | 100x100x80 | |

| External Dim(W*H*D) | 107x145x68 | 120x164x92 | 122x169x112 | 162x184x112 | |

| Temperature range | RT+10℃~70℃ | ||||

| Humidity range | 50%~90%RH | ||||

| Radiation intensity of xenon lamp | 550W/m² | ||||

| Spectral wavelength region | 290nm-800nm | ||||

| rainfall time | 0-9999/min | ||||

| Total power xenon lamp | 2KW/6KW | ||||

| type of cooling | forced air cooling/water-cooling | ||||

| Interior | SUS#304Stainless steel plate | ||||

| External material | Coating or SUS#304Stainless steel plate | ||||

Power Source | AV:220V/380V 50/60Hz | ||||

Produce Making Details:

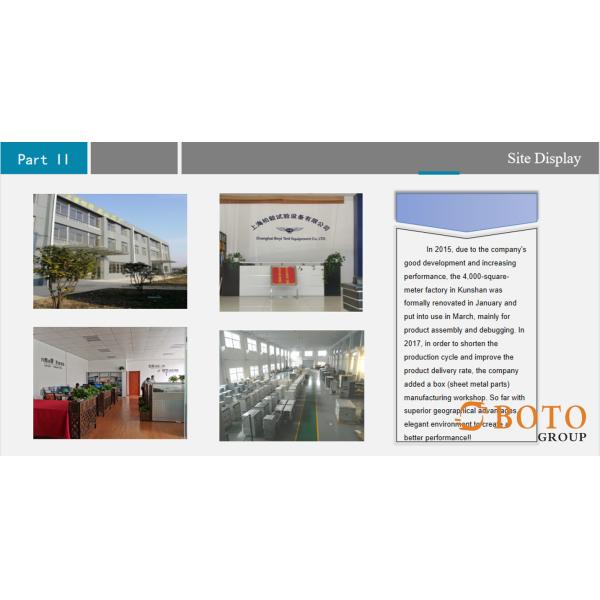

Our company:

Packing/Shipping:

During the whole business process, we offer Consultative Selling service.

1)Customer inquiry process:

Discussing testing requirements and technic details, suggested suitable products to customer to confirm. Then quote most suitable price according to customer requirements.

2)Specifications customize process:

Drawing related drawings to confirm with customer for customized requirements. Offer reference photoes to show the proucts appearance. Then, confirm the final solution and confirm final price with customer.

3)Production and delivery process:

We will produce the machines according to confirmed PO requirements. Offering photoes to show production process.

After finish production, offer photoes to customer to confirm again with the machine. Then do own factory calibration or third party calibration(as customer requirements). Check and test all the details and then arrange packing.

Deliver the products in confirmed shipping time and inform customer.

4)Installation and after sale service:

Defines installing those products in the field and providing after-sales support.

|

|

DIN50021 Xenon Lamp Aging Chamber Lab Machine Xenon Arc Test Chamber Manufacturer Images |